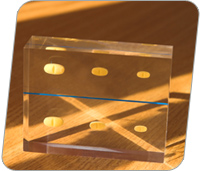

The plexiglass, also called acrylic glass, thanks to its optical and mechanical characteristics, is used in various fields ranging furnishing engineering, optics and medicine. The high transparency, long life without any loss of quality, and ease of processing, are just some of its peculiarities. Tecnoplastica uses methacrylate, thus obtaining a finished product of high quality both as robustness that as aesthetic effect. We are able to shape plates, blocks, pipes, square bars, round acrylic cast and extruded in order that it be applied in the realizations of windows, skylights, domes, tunnels, vaults, parapets, noise barriers, street furniture and interior design, set design, advertising equipment, stands, greenhouses and applications in the field of construction.

For years, we attach importance to the working of plexiglass. Thanks to its characteristics of transparency infrangibility is used in the manufacture of glass Safety and items similar in accident prevention garrisons, artwork of furniture or architectural genre. We have reached a processing that traditional thermoforming machines are not able to apply to the processing of this material.

Assure the brilliance, luster, the raw material, also by machining are able to offer a decrease of the thickness of the material before thus reducing production costs. Rub all profiles rettilinii and curvilinii Glue the finished products or components through bi hill aesthetic products for exhibitors or whatever Making straight and curved folds of thicknesses greater than one centimeter